Services

Underwater Hull Cleaning

Marine vessels face constant exposure to marine growth like algae, barnacles, and biofilms that accumulate on their hulls over time. This accumulation not only increases drag but also results in reduced speed, higher fuel consumption, and greater wear and tear on the vessel’s propulsion system. At JVS Diving and Marine Services, we specialize in providing professional underwater hull cleaning services designed to restore your ship’s efficiency and maintain its optimal performance.

Using advanced cleaning techniques and cutting-edge equipment, our expert divers meticulously remove all forms of marine growth while preserving the integrity of the vessel’s anti-fouling coatings.

Underwater Propeller Polishing

A vessel's propeller plays a crucial role in its propulsion system, and its performance directly impacts the ship’s speed, fuel efficiency, and operational costs. Over time, propellers are subjected to harsh underwater conditions, leading to the buildup of marine growth, corrosion, and surface roughness. These factors significantly hinder propulsion efficiency, resulting in increased fuel consumption and decreased vessel performance.

At JVS Diving and Marine Services, we provide expert underwater propeller polishing services to restore and enhance the performance of your ship’s propeller.

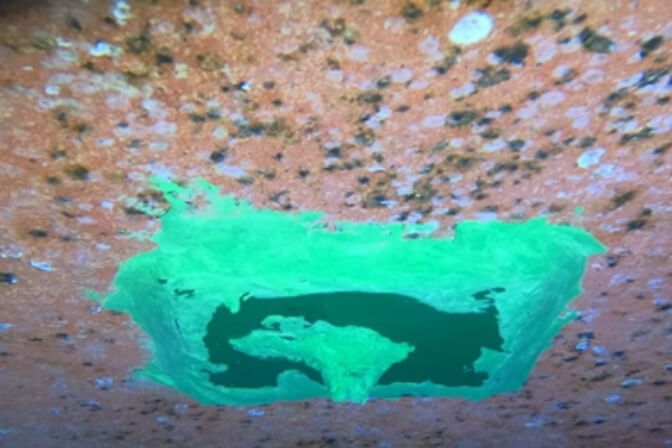

Underwater Doubler Plate Fixing with Epoxy Putty

Doubler plates are used to reinforce damaged or weakened areas of a vessel’s hull. JVS provides underwater doubler plate fixing services using high-quality epoxy putty to create a strong and durable bond. This service is essential for maintaining the structural integrity of your vessel and preventing further damage.

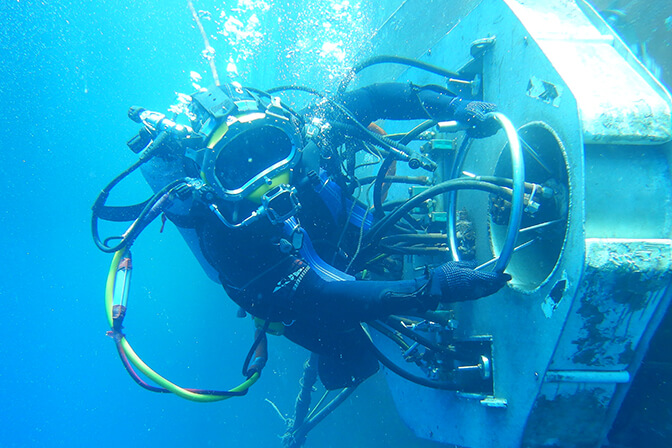

Underwater Bow Thruster Tunnel Cleaning and Blades Polishing

Bow thrusters are an indispensable component of modern vessels, providing the maneuverability needed to navigate tight spaces, such as ports, harbors, and canals. However, the tunnels and blades of bow thrusters are prone to the accumulation of marine growth, which can impair their performance and reduce efficiency. JVS Diving and Marine Services offers comprehensive cleaning and polishing services for bow thruster tunnels and blades.

Underwater Bow Thruster Grid/Sea Chest Grid Fixing

Bow thruster and sea chest grids play a vital role in protecting a vessel's internal systems by preventing the ingress of debris, which could cause significant damage and reduce operational efficiency. Over time, these grids may become loose, misaligned, or damaged due to marine growth, harsh underwater conditions, or operational wear and tear. Prompt repair and realignment of these grids are essential to avoid performance issues and costly breakdowns.

Underwater Sea Chest Grids Internal and External Cleaning

Sea chest grids are a critical component of a ship’s water intake system, allowing seawater to flow into cooling, ballast, and other onboard systems. Over time, these grids can become clogged with marine debris, such as seaweed, barnacles, and other obstructions. If left unchecked, this buildup can disrupt water flow, compromise the efficiency of shipboard systems, and potentially lead to costly repairs or downtime.

Underwater Plugging and Unplugging of Overboard Pipe

Overboard pipes play a crucial role in a vessel’s operational systems, including water intake and discharge. At JVS, we offer specialized underwater plugging and unplugging services for overboard pipes, ensuring that these systems remain functional and free from blockages.

Underwater Blanking of Sea Chest Grids, Speed Log, and Echo Sounder

JVS provides professional underwater blanking services for sea chest grids, speed logs, and echo sounders, ensuring safe and efficient maintenance. Our divers use high-quality blanking plates and sealing materials to create a watertight barrier, allowing work to be carried out without the need for dry-docking.

Underwater IWS CCTV Survey with Class and Without Class Attendance

In-Water Surveys (IWS) are an essential part of modern vessel maintenance, providing an alternative to dry-docking for assessing the condition of submerged components. These surveys save time and costs while offering shipowners valuable insights into the state of the hull, propellers, rudders, and other critical underwater structures. At JVS Diving and Marine Services, we specialize in conducting high-quality IWS CCTV surveys, both with and without class society attendance, tailored to the unique requirements of each client.

Underwater Hull Paint Survey as per Paint Manufacturer Requirement

The hull paint system plays a crucial role in protecting a vessel from marine growth and corrosion, ensuring smooth operation and reduced maintenance costs. JVS Diving and Marine Services offers specialized underwater hull paint surveys that comply with manufacturer requirements, helping shipowners maintain the integrity of their paint systems. Using advanced tools and underwater imaging systems, we document every aspect of the paint system, identifying areas that require touch-ups or complete reapplication.

Our comprehensive reports are aligned with the guidelines of leading paint manufacturers, ensuring that shipowners receive accurate recommendations for maintaining their hull coatings.

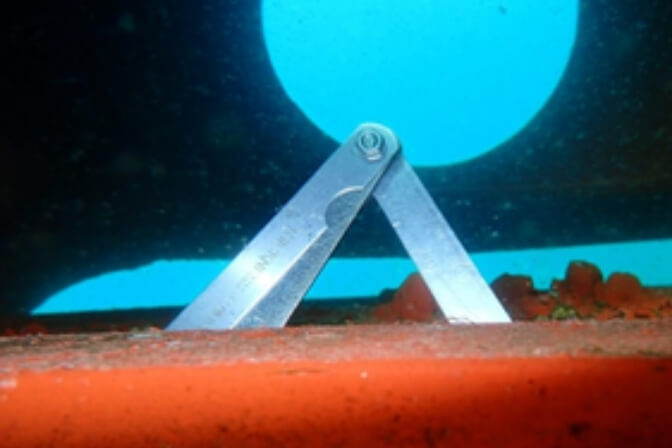

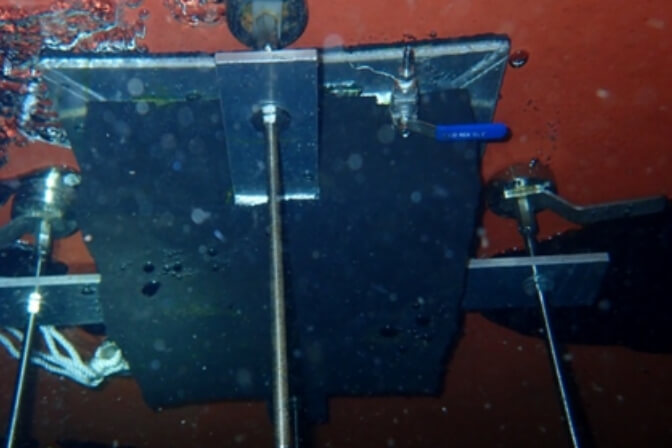

Underwater Propeller Shaft Reading Using Poker Gauge

The propeller shaft is a critical component of a ship’s propulsion system, and its condition directly affects the vessel’s performance and safety. Misalignment or excessive wear on the shaft can lead to vibration, increased fuel consumption, and mechanical failures. JVS Diving and Marine Services offers precise underwater propeller shaft readings using poker gauges to ensure the integrity of your propulsion system.

Underwater Rudder Pintle Clearance Measure

The rudder is one of the most critical components of a vessel’s steering system, and its performance depends on maintaining proper pintle clearance. At JVS Diving and Marine Services, we provide precise underwater rudder pintle clearance measurement services to ensure the reliability of your vessel’s steering system.

Using advanced tools and techniques, our divers measure the clearance between the rudder and its pintles, identifying any deviations from recommended tolerances.

Underwater Still Photo Inspection

Visual documentation is a cornerstone of effective ship maintenance, providing detailed records of a vessel’s condition for assessment and planning. JVS Diving and Marine Services offers high-resolution still photo inspections of underwater components, capturing critical details that aid in identifying wear, damage, or fouling.

Underwater Normal Video Inspection

JVS Diving and Marine Services offers a specialized underwater scrubber overboard pipe internal inspection service using advanced borescope cameras. This state-of-the-art inspection method enables a thorough evaluation of the internal condition of the discharge pipes without the need to dismantle the system. The borescope, equipped with a flexible probe and high-resolution imaging capability, allows our team to capture clear, detailed visuals of the pipe interiors, making it easier to detect corrosion, cracks, scaling, and other obstructions that may impede the scrubber’s performance.

One of the key advantages of our borescope inspection service is that it is non-intrusive, meaning that the system can remain operational during the inspection. Traditional inspection methods often require disassembly or system shutdown, which can be costly and result in significant downtime for the vessel.

Underwater Scrubber Overboard Pipe Internal Inspection Using Borescope Camera

Scrubber systems play a crucial role in reducing emissions and ensuring compliance with environmental regulations, particularly in meeting IMO 2020 standards. However, the overboard pipes associated with these systems are prone to debris accumulation, scaling, and blockages over time.

These issues can impact the performance of the system, potentially leading to operational inefficiencies and regulatory non-compliance. With JVS’s expertise, you can maintain your vessel’s emission control systems efficiently, ensuring long-term operational success and environmental responsibility.

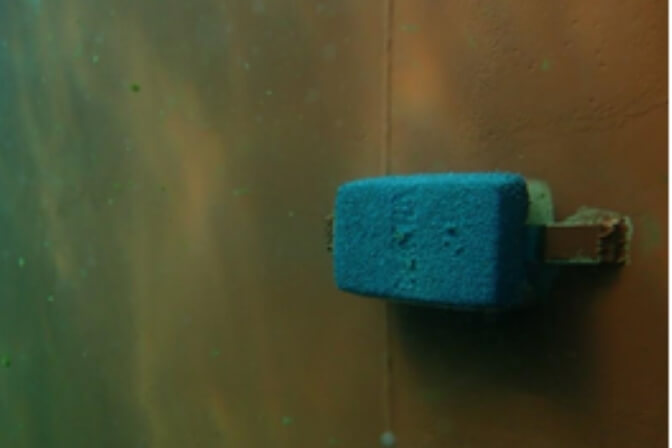

Underwater Anode Fixing

Anodes are a critical component of cathodic protection systems, safeguarding a vessel’s hull and other submerged parts from corrosion. Over time, these anodes wear out and need to be replaced to ensure continuous protection. At JVS Diving and Marine Services, we provide professional underwater anode fixing services to maintain the structural integrity of your vessel.

Our divers are skilled in the installation of sacrificial anodes, ensuring they are securely attached to the hull and other components.

Underwater Epoxy Putty Covering for Anodes

To enhance the durability and performance of sacrificial anodes, JVS Diving and Marine Services offers professional underwater epoxy putty covering services. This additional protective layer shields the anodes from mechanical damage, debris impact, and harsh environmental conditions, ensuring they remain effective over an extended period.

Our team of expert divers applies high-quality epoxy putty with precision, forming a seamless and durable coating that can withstand the challenging underwater environment.

Underwater Rope Guard Blanking for Repair

The rope guard protects the propeller shaft from damage and entanglement, but it may require repairs or replacement over time. By creating a watertight seal around the rope guard, our divers enable maintenance work to be carried out without compromising the vessel’s operational readiness.

Underwater Cofferdam Installation

Underwater cofferdam installation is a highly specialized service that allows for dry repairs and maintenance of submerged vessel components without the need for dry-docking. This innovative solution is particularly valuable for addressing issues such as leaks, hull damage, and component replacement while minimizing operational downtime.

At JVS Diving and Marine Services, we are experts in the installation of temporary cofferdams to create a dry working environment underwater.

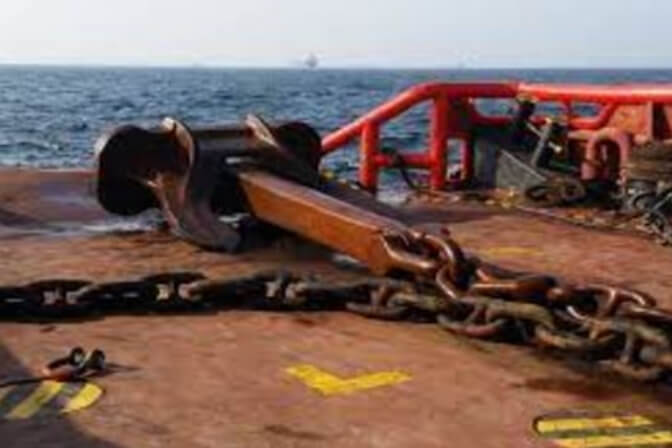

Underwater Diving Support for Anchor Handling Operations

Anchor handling operations are vital yet complex processes that involve deploying, retrieving, and repositioning anchors to ensure vessel stability during operations. These tasks require precise coordination and experienced professionals to avoid operational delays, equipment damage, or safety hazards. JVS Diving and Marine Services offers expert underwater diving support for anchor handling operations, ensuring safety, efficiency, and compliance with maritime standards.

Our team of highly trained and certified divers provides essential services, including anchor inspection, chain maintenance, and debris removal. During deployment or retrieval, anchor systems can accumulate marine growth or become entangled with debris such as fishing nets or cables. Our divers meticulously inspect the anchor and its chain to identify and resolve any issues, ensuring that the system remains fully functional.

Underwater Fishing Net/Rope Removal from Rope Guard and Propeller Shaft

Fishing nets, ropes, and marine debris pose a significant threat to the performance and safety of a vessel’s propulsion system. These materials often become entangled around the propeller shaft and rope guard, leading to reduced thrust, increased fuel consumption, and even mechanical failure if not promptly addressed. Such entanglements can also cause excessive strain on the propeller, bearings, and related components, resulting in costly repairs and extended downtime.

JVS Diving and Marine Services offers professional underwater debris removal services to efficiently resolve these issues and restore the vessel's full functionality.

Above Water Level / Boot Top Cleaning Using High-Pressure Water Jet Machine

Maintaining the area above the waterline, commonly referred to as the boot top, is crucial for preserving a vessel’s appearance and structural integrity. Continuous exposure to harsh marine conditions leads to the accumulation of salt deposits, dirt, and marine growth on the ship’s exterior. Over time, this buildup can cause corrosion, weakening the vessel’s structure and affecting its overall performance.

JVS Diving and Marine Services provides professional boot top and above-water cleaning using high-pressure water jet machines. This method is highly effective in removing stubborn contaminants without causing damage to the vessel’s paintwork or surface.